Best Practices Automotive Wiring Harness

Our design checklist for cable and wiring harnesses ensure that we have a full understanding of the requirements and that we can prevent errors before they occur. If you are rewiring an early car or truck make life easy on yourself and get a complete harness like this Painless Performance 18-circuit universal harness.

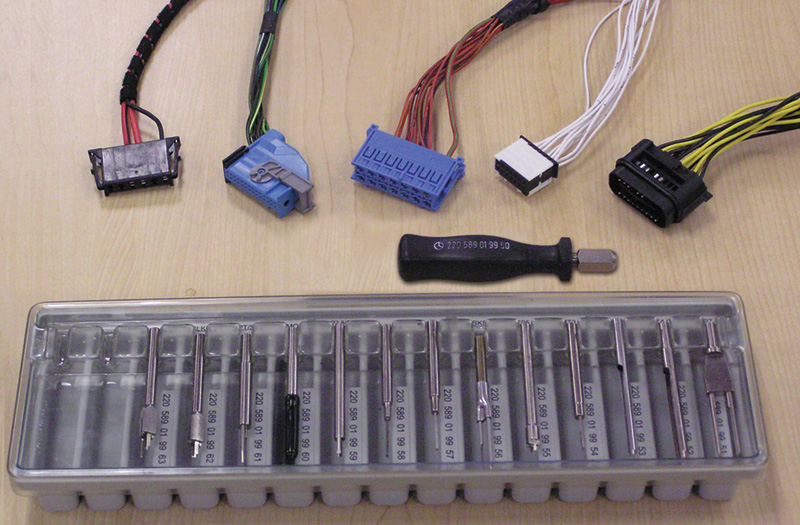

Mercedes Benz Wiring Harness Repair Automotive Tech Info

Mercedes Benz Wiring Harness Repair Automotive Tech Info

Note wire colors along with any text you may want printed or labeled on your wires to help identify circuit names.

Best practices automotive wiring harness. Connector cable clamps and cable straps are properly set. Wire Harness Manufacturing Terms Tools and Tips of the Trade. Automobile wire harnesses are usually subjected to extreme conditions.

Identify potential problems posed by the physical environment such as electrical interference heat and cold moisture radiation and more. 2013 Find The Best Manufacturer Sep 24 2013. Best Practices for Wire Harness Design For a harness to function properly in its physical environment the equipment must adhere to a range of best practices.

The Wiring Harness Manufacturers Association Manufacturer Members understand the critical role that the wire harness plays in the vehicleIt is a set of wires connectors and terminals that transmits information and electric power to deliver function to the vehicle. For example GXL wiring is very typical for automotive wiring while a. 2019 Best Practices for Design of Enclosures with Batteries Dec 3 2019.

How Lectric Limited Inc. Typically physical mockups are the best way to ensure correct wire harness routing. Circuit protection is critical.

As a matter of fact your vehicles original wiring was only designed to last 10 years before it started to deteriorate. Our wiring harnesses are brand-new and better than NOS. The harness is fastened to the engine and chassis which subjects the harness to excessive heat cold and vibration.

Using a 3D CAD system the wire paths are specified throughout the aircraft. As we all know the automotive wiring harness is the main body of the circuit of the automobile which is equivalent to the blood vessels and nervous system of the automobile. Herere tips tricks and best practices to make your next install a breeze.

The ComponentsA typical aftermarket wiring harness consists of about 47 12 miles of wire give or take a dozen or two miles. These conditions often cause the wire harness to stretch and contract causing undue stress sometimes resulting in a broken wire. In addition connector disconnects will determine when a wire goes through a bulkhead.

Of all the unwelcome drama a performance vehicle can inflict on its owner chasing electrical gremlins is perhaps the most frustrating. Lets face it folks NO automobile manufacturer ever designed a wiring harness to last 40-70 years. How wire harness manufacturers can achieve success amid a changing Nylon 66 market by Robert Rensa Panduit Created as an alternative to silk in the 1930s the practical applications for Nylon 66 werent as vast then as they are now.

Each wire in a wire segment is then uniquely identified see Chapter 4 Wire. While not the most glamorous project-car task wiring is crucial to a well-running vehicle. Best Seller in Automotive Replacement Electrical Wiring Harnesses Nilight - NI -WA 06 LED Light Bar Wiring Harness Kit - 2 Leads 12V On Off Switch Power Relay Blade Fuse for Off Road Lights LED Work Light 2 Years Warranty.

Dating all the way back to 1985The Team at Falconer Electronics Inc. Without the wiring harness there is no automobile circuit and it is a very important automobile component. Fuses are the preferred method to protect our wiring harness because while they are terminable they offer a greater level of protection.

There are many types of wire with variations including voltage ratings insulation material bare or plated copper etc each suited to different uses. Insulation chosen for the aircraft wire harness design engineer select wire part number to use. Harnesses exhibit a neatly organized layout with smooth bends and sufficient stress relief.

3 Protection Level Critical. Wire Harness Manufacturing is our foundation. My harness would have worked but with the input of someone more knowledgeable I learned a couple of best practices that will simplify the system and ensure Ill be safe riding it.

New old stock THE PROBLEM. FEI takes tremendous pride in manufacturing amazing products for our customers. Basic knowledge automotive wiring harness.

With the recent proliferation of 3D mechanical design software it has become much easier faster and cost-effective to create a virtual prototype by routing harnesses within a CAD model of the product that is. But they can be time consuming and expensive. Thankfully theyre usually different colors and labeled to boot.

An average transportation vehicle uses many wires when stretched out they can extend for miles. We doubled the fuse count from the traditional one and set them so the ignition has its own fusemeaning if the lights short out or cause issue enough to blow. Its in our blood.

The harness has virtually everything you need to wire the whole truck including a preterminated fuse block and color-coded circuits for lights gauges and dash electric fuel pump. Fuses are our preferred method of circuit protection. In fact prior to becoming one of the most in-demand substances on the planet.

There is ample documentation to substantiate this claim. In addition as a Wire Harness Manufacturer assembling and delivering superior products is our mission. Tapes an automotive wiring harness using an original 60 year old taping machine to ensure a factory-original looking wiring har.

Wiring Harness Pcm Connector Harness Wire Automotive Mechanic

Wiring Harness Pcm Connector Harness Wire Automotive Mechanic

Electric Vehicle Relay Center Motorcycle Camping Gear Relay Camping Gear

Electric Vehicle Relay Center Motorcycle Camping Gear Relay Camping Gear

Automotive 5 Pin Relay Common Wire Colors Automotive Care Automotive Repair Automotive Technician

Automotive 5 Pin Relay Common Wire Colors Automotive Care Automotive Repair Automotive Technician

Saab Trionic 5 Conversion Wiring Harness Eeuro 101e00010 Eeuroparts Com Harness Boat Trailer Lights Car Repair Diy

Saab Trionic 5 Conversion Wiring Harness Eeuro 101e00010 Eeuroparts Com Harness Boat Trailer Lights Car Repair Diy